The editorial

By Adéyèmi Zacharie OKIRI

Deputy General Director

The Ciment Bouclier plant places workers at the center of all its activities. We prefer to talk about talent because we have a particular talent for a function. These talents must be highlighted and developed continuously through regular training. This allows us to guarantee quality products and quality services.

A.Z. OKIRI

Deputy General Director

SCB in pictures

Our activity, our communication, our clients

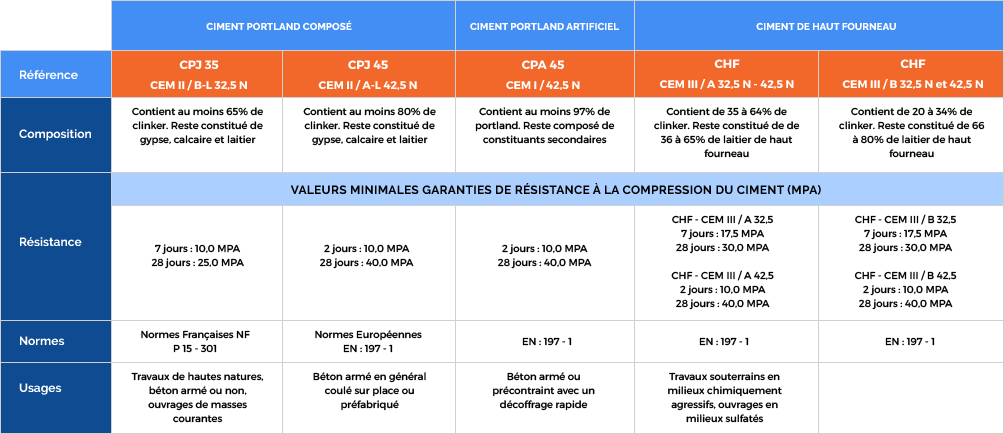

Our Cement Range

Our different cements and their specificities

To meet the specific needs of its clients, the BOUCLIER plant has a wide range of cement available to them :

Cpj 35

CEM II / B-L 32,5 N

The CPJ 35 is a Portland cement with additions. It contains at least 65% of Clinker, the rest being either limestone, Laitier, Pouzzolanes etc. then calcium sulfate to regulate the take.

The CPJ 35 is used in works of all kinds, reinforced concrete or not, for usual mass works.

CPJ 45

CEM II / A 42,5 N

The CPJ 45 is a Portland cement with additions. It contains 80% of Clinker, the rest being either limestone, Laitier, Pouzzolane and Gypsum to regulate the take.

It is used in reinforced concrete in general, cast on the spot or prefabricated.

CPA 45

CEM I / 42,5 N

The CPA 45 is a Portland artificial cement. It contains at least 97% of Portland Clinker. The rest is made up of secondary components.

Le CPA 45 is used in reinforced or pre-constrained concrete with fast de-coffering.

CHF

CEM III / A ou B 32,5 - 42,5 N

Blast-furnace cement containing respectively 35% to 64% of Clinker for CHF-CEMIII and 20% to 34% for CHF-CEMIII/B, the remaining components being Laitier with possibly a maximum of 5% of secondary components.

Blast-furnace cements are used in underground works in chemically aggressive environments, works in sulfated environments and works requiring little hydration heat; mass concrete and works in concrete, reinforced or not, and works at the sea.

Characteristics of Bouclier cements by resistance and use

Our cement plant

The stages of the industrial process

The Benin Cements Company (SCB) is a grinding plant with a high-performance laboratory which permits us to ensure at the upstream and downstream stages that the cement produced is in accordance with production standards and meets the requirements of resistances and exceptional fineness. So, to achieve this goal, three major controls are carried out :

The systematic control of all the raw materials for the production of cement during all the unloading stage so as to ascertain their quality.

The control of the cement exiting the grinder : every hour, a portion of cement exiting the grinder (about 1kg) is taken by samplers for production monitoring tests, namely: measuring the finesse by the permeability of Blaine, refuse on sieve (1 micron), and the determination of loss to fire. A complete chemical analysis is carried out by the spectrometer every three hours. The results of those analyses, together with the date, are registered on the daily control sheet planned for that purpose. Those results are sent to the chief grinder. It the result deviates from the set orders, adjustments are made for correction. In addition to controls made on-site, a medium sample is made up for each grinding campaign for the resistance control at different ages.

The objective of those analyses is to control the quality during the grinding of the cement, to modify the adjustment in case of driftings, to ensure regularity during the grinding of cement.

The control of the shippings of finished products : a cement sample is taken every day by samplers during bagging. Physical and mechanic trials related to the control of the finished products are carried out: mechanical resistance, fineness (Blaine), refuse, take trials and expansion, and then complete chemical analysis by spectrometer. The objective is to maintain conformity and quality at the level of the cement delivered to the customer. By the way, let us mention that an external control is also carried out by the National Center for Trials and Research of Public Works (CNERTP) which comes three times a week to take samples for production control.

Bagging is the last stage on the production line. It is in this section that the cement is bagged and sent directly into trucks.

When an operator positions a bag and presses the start button, the block starts, the electrovalve opens thanks to its jack. When the digital balance system detects the strict 1 kg weight of bag of cement, the electrovalve shuts itself by means of the balance. At once, the bag falls on the conveyor belt located beneath the bagger.

Cement is obtained by mixing clinker, limestone, and gypsum in well defined proportions.

The different materials from the stocking are discharged into their respective measure and sent into the grinder by means of a feeding belt. The mixture of clinker, limestone, and gypsum is then transformed into powder in the above-mentioned grinder. This powder is vacuumed through the exit cone in the trommel. At the exit of the trommel, cement is collected which is transported into silos by means of transportation devices (screw or chain transporter, elevators). Refuses (wastes contained in materials, iron fragments, and pieces of un-ground materials) are collected at the level of the trommel by means of a sieve.

Our commercial service

The BOUCLIER plant has, in addition to its sales depots located in the large towns of Benin, through the agency of its distributors, many sales points across the whole Benin.

Thanks to a top-of-the-art logistics, we are able to deliver BOUCLIER cement to our clients across the country, even in the remotest localities. This is one reason, among others, which brings corporations in charge of realizing heavy works in the property business sector and Public Works to prefer Bouclier cement.

Still for the purpose of better serving our clients and consumers and further reinforce our distribution network, we regularly make mobile sales in localities distant from Benin epicenters. This consists in making direct sales on trucks specially destined for that purpose. This also permits the clients to buy cement on the spot.

One of the goals regarding distribution is for the Bouclier cement to be accessible at any time and in all the localities of Benin. By means of the major logistical equipment put in place by the Bouclier plant commercially through the availability of containers for stocking cement in sacks or silos with a capacity of 75 tons for cement in bulk and regarding transport with an important fleet of trailer trucks and tipper trucks for the transport of cement in bags and tanks for the transport of cement in bulk, we are able to readily and precisely meet the needs of our clients and to ensure timely deliveries to the satisfaction of our clients.

Sustainable Developpement

Health, Safety and Environment

The Benin Cement Company, SCB Bouclier has taken strict and effective steps to respect environmental standards. In this regard, an important investment has been devoted through installation of latest-generation equipment in the field, followed by the set up of a Health, Safety, and Environment service (HSE).

The HSE department of the Benin Cements Company Bouclier was created in 2012, pursuant to the memo N°045 MTEAS/DC/DT/-SST of January 14, 1994. Its main goal is to achieve environmental felicity through prevention and management of risks, reduction of pollutions and taking into account the well-being of the surrounding population. The activities performed by the HSE of SCB Bouclier regroup : Safety management, Hygiene and maintenance, Training and awareness-raising, Environmental issues management.

Regarding health risk prevention, we conduct periodical awareness-raising sessions on the importance of abiding by hygiene and safety rules.

It is also important to add the creation of a health and safety at work committee who organizes a day of idea exchange on malaria and Sexually Transmissible Diseases, AIDS specially.

For the safety of both internal and external actors, we have implemented numerous arrangements :

- Control and monitoring of activities

- Control of fire and work permits

- Control and monitoring of fire-fighting equipment

- Control of the wearing of individual protection equipment (EPI)

EPIs

We provide our employees and actors with individual protection equipment (helmet, safety shoes, work clothes, breathing protection masks, protection glasses, anti-noise headphones).

This equipment is protection tools against one or several risks likely to threaten out personnel’s health or safety. Wearing them is required of anybody whose activity exposes him or her to nuisances or various risks. The choice of the type of EPI is based on the analysis of the work position of workers, which permits us to think of protection equipment appropriate to risks and adapted to the worker.

The major environmental issue encountered within the company is the emission of particles in the atmosphere.

Atmospheric rejections

Atmospheric rejections within the company are essentially related to emissions of dust into the atmosphere. In total, 18 filters with handles have been installed at the level of fixed sources. Those filters collect the dust and let purified air escape into the atmosphere. These operational measures have permitted a reduction of 90% of the atmospheric pollution that we generate. In addition to the filters with handles, we have put in place a fogging system whose action permits us to avoid the rising of dust into the environment.

Sound pollution

Sound nuisances within the plant come essentially from the operation of generators. To reduce those nuisances, all the generators have been equipped with silencers.

Social issues

Every day, we water and maintain the streets connected to the plant and we participate, together with the Municipality, in the periodical maintenance of the monument to the dead located at the left wing of the plant.

Our news

The Bouclier cement highlights

Our achievements

The Bouclier cement, property project and Beninese Public Works partner

Employment and Intership

You wish to join us

In constant search for talented people, the BOUCLIER plant makes every effort to develop internally the skills of its staff.

If you want to join a motivated team and put your know-how at the service of the development of our activity, do not hesitate to inform us of your interest by filling out this form. We will reply to you as soon as possible.

Contact us

Adress :

Placodji - 01 BP 448

Cotonou

Republic of Benin

Phone number :

+229 21 31 37 03

+229 21 31 37 83

Fax number :

+229 21 31 50 74

Email adress :

serviceclient @ cimentbouclier.com